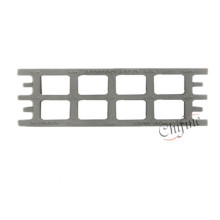

Customized High Quality Drainage Grating

Customized High Quality Drainage Grating

| Payment Type: | L/C, T/T, Western Union, Paypal, Money Gram |

|---|---|

| Min. Order: | 1 |

| Productivity: | 300tons Per Month |

|---|---|

| Place of Origin: | Qingdao, China |

| Supply Ability: | 300tons Per Month |

| Certificate: | CE, ISO |

Basic Info

Model No.: CFMS-145

Product Description

Model NO.: CFMS-145 Application: Steel Structure Walkway, Drain Cover Manufacturing Method: Machine Welding Product Name: Drainage Grating Material Available: Stainless Steel, Carbon Steel Usage: Automobile; Agriculture, Machinery, Industry, etc Inspection: by Professional Measuring and Testing Devices OEM: Available Trademark: CHIFINE Origin: Qingdao, China Certification: CE, ISO Shape: Tooth Shape Material: Carbon Steel Brand Name: Chifine Model No.: Street Products 145 Dimension: Can Be Customized for Your Requests Country of Origin: China Package: Wooden Case or as Your Requests Specification: ISO9001: 2008 HS Code: 7314200000 The specification of Steel Bar Grating :

-Material:carbon steel, stainless steel.

-Finished:Hot-dip galvanized, Electro galvanized, Painting

-Anti-rust,anti-slip more than 10 years

Description:

1) material: carbon steel or stainless steel

2) cross bar pitches: approximately 24-200mm,of which 50mm,76mm and 100mm are recommended.

3) Steel grating is made by the world first-class equipment,which can arrange the bearing bar and cross bar in longitude and latitude order to certain distance.cross bar is pressed into the bearing bar by high tension resistance weldingring which is controlled by computer.so we can produce high quality gratings with firm welding, smooth surface and high strength.

4) Surface process of gratings: there are three types: hot-dipped galvanized ,electro-galvanized and spraying brushing and soaking. anti-acid and alkali corrosion capacity the range PH6 to PH12.5,a stable protective film will be formed on the zinc surface.it has good anti-corrosive property.

5) Finish treatment: Hot dipped galvanized, cold dipped galvanized, spray painting, dip anti-rust oil, can prevent oxidation.

6) Surface type: Flat type, serrated type, I shape type(According to requirement made different protective treatment).

Steel Bar grating size(as reference)

Welded steel grating:

Advantages:

1) Saving materials: this is the best way to save in materials under same loading conditions and accordingly in materials of structural rack as well.

2)Saving Investment: Less material, Less labor cost, short time limit, non cleaning and maintance.

3)Convenient operation: One person is ok to finish operation that fix rack.

4)Short time limit: Non reprocessing and being assembled quickly

5)Morden style: Nice shape,excellent design and good ventilation

6)Light wight:it is very esy to fix

7)NO water,snow and dirt on surface outside

8)Reducing aerdynamic drag:There is less damage as good ventilation Contact us if you need more details on Floor Drain. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Drainage、Drain Strainer. If these products fail to match your need, please contact us and we would like to provide relevant information.

-Material:carbon steel, stainless steel.

-Finished:Hot-dip galvanized, Electro galvanized, Painting

-Anti-rust,anti-slip more than 10 years

Description:

1) material: carbon steel or stainless steel

2) cross bar pitches: approximately 24-200mm,of which 50mm,76mm and 100mm are recommended.

3) Steel grating is made by the world first-class equipment,which can arrange the bearing bar and cross bar in longitude and latitude order to certain distance.cross bar is pressed into the bearing bar by high tension resistance weldingring which is controlled by computer.so we can produce high quality gratings with firm welding, smooth surface and high strength.

4) Surface process of gratings: there are three types: hot-dipped galvanized ,electro-galvanized and spraying brushing and soaking. anti-acid and alkali corrosion capacity the range PH6 to PH12.5,a stable protective film will be formed on the zinc surface.it has good anti-corrosive property.

5) Finish treatment: Hot dipped galvanized, cold dipped galvanized, spray painting, dip anti-rust oil, can prevent oxidation.

6) Surface type: Flat type, serrated type, I shape type(According to requirement made different protective treatment).

Steel Bar grating size(as reference)

| Cross Rod Pitch | load Bar Pitch | steel bar grating load Bar Specification(Width×Thickness) | |||||

| 20×3 | 25×3 | 32×3 | 40×3 | 20×5 | 25×5 | ||

| 30 | 100 | G203/30/100 | G253/30/100 | G323/30/100 | G403/30/100 | G205/30/100 | G255/30/100 |

| 50 | G203/30/50 | G253/30/50 | G323/30/50 | G403/30/50 | G205/30/50 | G255/30/50 | |

| 40 | 100 | G203/40/100 | G253/40/100 | G323/40/100 | G403/40/100 | G205/40/100 | G255/40/100 |

| 50 | G203/40/50 | G253/40/50 | G323/40/50 | G403/40/50 | G205/40/50 | G255/40/50 | |

| 60 | 50 | - | G253/60/50 | G253/60/50 | G403/60/50 | G205/60/50 | G255/60/50 |

| Cross Rod Pitch | load Bar Pitch | steel bar grating load Bar Specification(Width×Thickness) | |||||

| 32×5 | 40×5 | 45×5 | 50×5 | 55×5 | 60×5 | ||

| 30 | 100 | G325/30/100 | G405/30/100 | G455/30/100 | G505/30/100 | G555/30/100 | G605/30/100 |

| 50 | G325/30/50 | G405/30/50 | G455/30/50 | G505/30/50 | G555/30/50 | G605/30/50 | |

| 40 | 100 | G325/40/100 | G405/40/100 | G455/40/100 | G505/40/100 | G555/40/100 | G605/40/100 |

| 50 | G325/40/50 | G405/40/50 | G455/40/50 | G505/40/50 | G555/40/50 | G605/40/50 | |

| 60 | 50 | G325/60/50 | G405/60/50 | G455/60/50 | G505/60/50 | G555/60/50 | G605/60/50 |

Welded steel grating:

| Type: | welded steel grating |

| Bearing bar centers: | 15-30, 40, 60, 80, 90 mm etc. with 30, 40 mm recommended. |

| Cross bar centers: | any greater than 30mm is ok. with 50, 100mm recommended. |

| Surface treatment: | G - galvanizedP - painted U - untreated |

Advantages:

1) Saving materials: this is the best way to save in materials under same loading conditions and accordingly in materials of structural rack as well.

2)Saving Investment: Less material, Less labor cost, short time limit, non cleaning and maintance.

3)Convenient operation: One person is ok to finish operation that fix rack.

4)Short time limit: Non reprocessing and being assembled quickly

5)Morden style: Nice shape,excellent design and good ventilation

6)Light wight:it is very esy to fix

7)NO water,snow and dirt on surface outside

8)Reducing aerdynamic drag:There is less damage as good ventilation Contact us if you need more details on Floor Drain. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Drainage、Drain Strainer. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Sand Casting

Premium Related Products

Other Products

Hot Products

ADC12 and A380 Aluminium Die Casting Chair Base for Table ChairEnamel Range Cast Iron Grate for Gas Burner BracketSquare Ductile Cast Iron D400 Manhole Cover with FrameCNC Lathe Part Sewing Machine PartsDie-Casting Aluminum Alloy Waterproof EnclosureScaffolding Ledger Head Part by Investment CastingCustom Valve Casting Parts with Sand CastingPrecision Metal Stamping Bracket with SteelTransmission Shaft Casting Yoke of AutoDie Casting for Auto Parts Alloy SteelStamping Metal Parts in Alloy SteelOpen Die Forging Iron CastingCustomization Sand Casting Carbon Steel for Auto PartSand Casting CNC Machining Parts Assembled Steel Vehical Body Iron CastingSand Iron Machining Machinery CastingIron Casting for Medical Devices Part