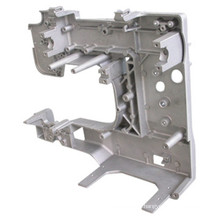

Aluminum Pressure Casting Part with Machinery Part

Aluminum Pressure Casting Part with Machinery Part

| Payment Type: | L/C, T/T, D/P, Paypal, Money Gram, Western Union |

|---|---|

| Min. Order: | 500 |

| Certificate: | SGS, CE, ISO 9001 |

|---|

Product Description

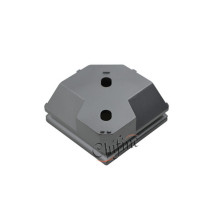

Die Casting Machine Type: Hot Chamber Die Casting Machine Application: Machinery Parts Material: Aluminum Casting Surface Quality Level: 1 Package: Pallet ,Manmade Wooden Case or as Your Requirement Origine: Qingdao Service: OEM and ODM Supply Ability: 10000 Piece/Pieces Per Month Die Casting Method: Precision Die Casting Machining: CNC Machining Tolerance Grade: 7 Certification: SGS, CE, ISO 9001:2008 Certificate: ISO9001 SGS CE Brand: Chifine Delivery Time: 30 Days After Receiving The Payment

Features:

1.Good wear-resistance,no deformation,long life cycle and so on.

2.We are an OEM supplier specializing in varous casting,forgings and machinings

3.According to customers drawings or samples by customers.

4.The quality of our products have all passed the international standards.

5.We have lots of experience in export,we export to many country,Mainly in America and Europe.

6.We can supply all kinds of die casting ,aluminum casting

7.OEM /Design/Buyer label survice offered

8.Having ISO9001:2008,RoHS certificate

9. High quality,Low price

Product Character:

-Customized Tool Design Drawings are Available;

-Molds are carefully machined to the closest tolerance using the latest equipment;

-The prototype should be created if the customer require;

-We offer secondary processing such as oil spraying, screen printing, assembly ect.

-Traceability is maintained from all inspection gages

-Mold repair and maintenance are also supported internally.

Qingdao Chifine Machinery Co.,Ltd is one famous company in China which specialized in various metal casting products with over 10 years experience located in Qingdao China.It covers a comprehensive range of forging, stamping, Sand Casting, Investment Casting, die casting and machining and was widely used in Agriculture machinery, Motor Vehicle, Architecture,Railway and Engineering

As a professional company, Chifine have four groups of experienced teams to be in charge of different work:

Project team-customer service

Engineering team-provide R&D and technical support

QC team-productive process control and incoming parts inspection

Warehouse team-warehouse management and logistic service

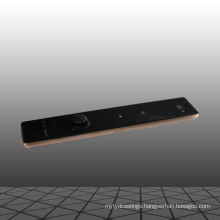

Aluminum die casting,Aluminum alloy die casting base

Contact us if you need more details on Low Pressure Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Low Pressure Cast、Investment Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Features:

1.Good wear-resistance,no deformation,long life cycle and so on.

2.We are an OEM supplier specializing in varous casting,forgings and machinings

3.According to customers drawings or samples by customers.

4.The quality of our products have all passed the international standards.

5.We have lots of experience in export,we export to many country,Mainly in America and Europe.

6.We can supply all kinds of die casting ,aluminum casting

7.OEM /Design/Buyer label survice offered

8.Having ISO9001:2008,RoHS certificate

9. High quality,Low price

Product Character:

-Customized Tool Design Drawings are Available;

-Molds are carefully machined to the closest tolerance using the latest equipment;

-The prototype should be created if the customer require;

-We offer secondary processing such as oil spraying, screen printing, assembly ect.

-Traceability is maintained from all inspection gages

-Mold repair and maintenance are also supported internally.

Qingdao Chifine Machinery Co.,Ltd is one famous company in China which specialized in various metal casting products with over 10 years experience located in Qingdao China.It covers a comprehensive range of forging, stamping, Sand Casting, Investment Casting, die casting and machining and was widely used in Agriculture machinery, Motor Vehicle, Architecture,Railway and Engineering

As a professional company, Chifine have four groups of experienced teams to be in charge of different work:

Project team-customer service

Engineering team-provide R&D and technical support

QC team-productive process control and incoming parts inspection

Warehouse team-warehouse management and logistic service

Aluminum die casting,Aluminum alloy die casting base

| Item | Description | |

| Molding technics | Die casting | |

| Material | ADC12,A380,AlSi12,A356,ZL102,YL104,YL112,YL113, and many other aluminum alloy are all acceptable. | |

| Dimension | As drawings or samples | |

| Surface treatment | Sandblasting, Painting, Powder coating, Anodize, Galvanized, Chrome plating, Nickel plating,etc. | |

| Die casting moulds | Cavity | Single or Multiple |

| Material | H13,DIEVAR,QDN,8407,2344V,TQ1,2343,SKD61, 45#steel,etc. | |

| Heat treatment | Hardened,Nitriding | |

| Hardness | HRC50~55 | |

| Mould feature | Advanced design, Novel structure, High precision, Quality materials, Long lifetime, Short delivery time | |

| Equipment | CNC precision mould engraving machine, CNC forming machine, CNC turning, EDM, Linear cutting machine, Die spotting machine(200T), Die casting machine(180T~1250T), Lathe, Grinding machine; CMM, Material detector, Hardness test device, spectrograph,etc. | |

| Software | CAD, UG, Pro/E, JSCAST-v8 of Japan, FLOW3D.v9.2 of America, etc. | |

| Quality certification | UKAS & SGS ISO9001:2008 | |

| Advantage | Quality | Insist on making every detail carefully always |

| Price | Maybe not the lowest, but must be the reasonable and competitive price | |

| Delivery | Never later than the delivery time in contract | |

| Service | 1. Wherever and whenever you send question, always get answer not more than 2 working days. 2. When have trouble during project processing, always find out problem and solve it first with customer, then ascertain where the responsibility lies,our party or customer side. | |

| R&D | Plentiful experience and skillful technique on die casting | |

| Team | United and positive team | |

Contact us if you need more details on Low Pressure Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Low Pressure Cast、Investment Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Die Casting

Premium Related Products

Other Products

Hot Products

ADC12 and A380 Aluminium Die Casting Chair Base for Table ChairEnamel Range Cast Iron Grate for Gas Burner BracketSquare Ductile Cast Iron D400 Manhole Cover with FrameCNC Lathe Part Sewing Machine PartsDie-Casting Aluminum Alloy Waterproof EnclosureScaffolding Ledger Head Part by Investment CastingCustom Valve Casting Parts with Sand CastingPrecision Metal Stamping Bracket with SteelTransmission Shaft Casting Yoke of AutoDie Casting for Auto Parts Alloy SteelStamping Metal Parts in Alloy SteelOpen Die Forging Iron CastingCustomization Sand Casting Carbon Steel for Auto PartSand Casting CNC Machining Parts Assembled Steel Vehical Body Iron CastingSand Iron Machining Machinery CastingIron Casting for Medical Devices Part